From heating elements to thermosensor technology and process control, the Lüdenscheid-based company hotset has been developing clever product and system solutions since 1973. One of the system solutions is the DH system (Dynamic Heat System). This is used for dynamic temperature control of injection molds. hotset is the technology leader in this field and has been a thermodynamics specialist for 50 years. Hotset GmbH is the sole manufacturer of the DH-System. The DH-System is the problem solver for various customers internationally for weld line problems of surface components. This system promotes the realization of quality-increasing, sustainable and energy-saving processes.

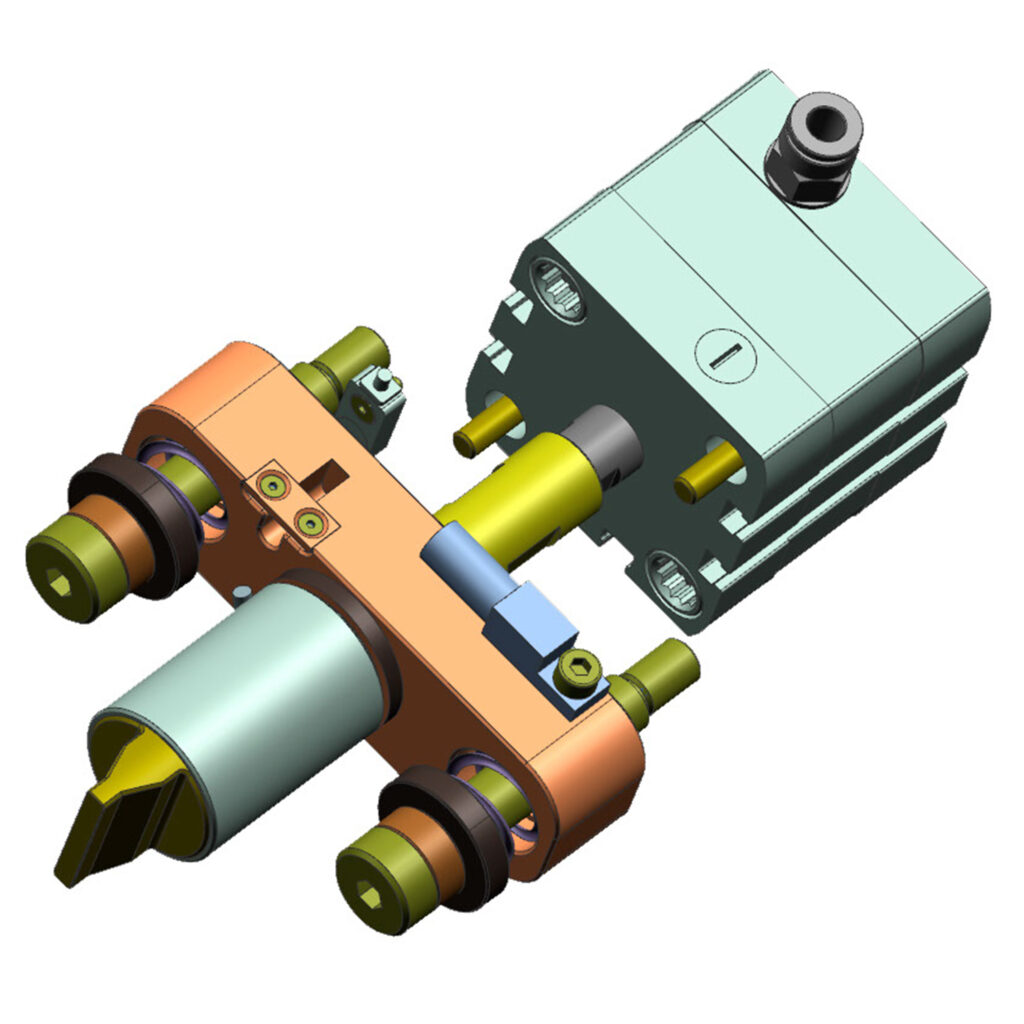

With the DH-System, hotset offers moldmakers in the injection molding industry a high-speed process for partial cyclic tempering, which on the one hand avoids optical defects (visible weld lines, dull halos, etc.), but on the other hand allows the realization of filigree fine structures and very thin wall thicknesses. Synchronized with the injection molding process, the cavities can thus be heated and cooled selectively or in sections at a fast heating rate of up to 60 K/s – enabling very rapid temperature changes in short cycles. Manufacturers of injection molded parts for the consumer and automotive industries can thus improve the surface quality of their products and open up new perspectives for lightweight construction and miniaturization.

The DH system acts faster, more accurately and more economically. Compared with the variothermal method, it is significantly more productive, economical and sustainable. It uses 50 times less energy in the heating phase alone.

WORLD MARKET LEADER PRODUCT/S

Location

Employees

Sales Volume

Establishment of production facility in Malta

Relocation to Hueckstraße

Foundation of Hotset Singapore Pte Ltd.

Foundation of Hotset America Corporation

Foundation of Hotset Heating Elements (Suzhou) Co. Ltd

Foundation of HIPL India Pvt Ltd. and development of the DH system

System center for industrial temperature control technology with own injection molding machine

Development D-System

Acquisition of iQtemp – system partner for conformal cooling and acquisition of Hotset UK

In the team for South Westphalia

c/o SIHK zu Hagen

Bahnhofstraße 18

D-58095 Hagen

Phone +49 (0) 2331 390-0

Email weltmarktfuehrer@hagen.ihk.de

An award from the IHKs in the team for South Westphalia

Menü

The entrepreneurial success of hidden champions usually results from successfully occupying niche markets.