Heinrich Georg GmbH is a specialist for sophisticated and economical solutions in coil processing and roll grinding, which combine classic mechanical engineering with intelligent process optimization and service solutions. Not least because of their high degree of automation, GEORG systems make an important contribution to process optimization and thus to the economic success of customers.

GEORG specializes, among other things, in rational production plants for the transformer industry. This includes the entire process consulting and optimization. After the successful market launch of the first GEORG transformer strip cutting lines – called „TBA“ for short – in 1960, this product name quickly became a generic term that has since become established worldwide in the market and also among competitors.

Through constant innovative new concepts and the consistent further development and automation of the GEORG plants, the Kreuztal-based company has been able to reach about three quarters of the world market with more than 1,000 TBA plants. This makes it the undisputed world market leader in this segment.

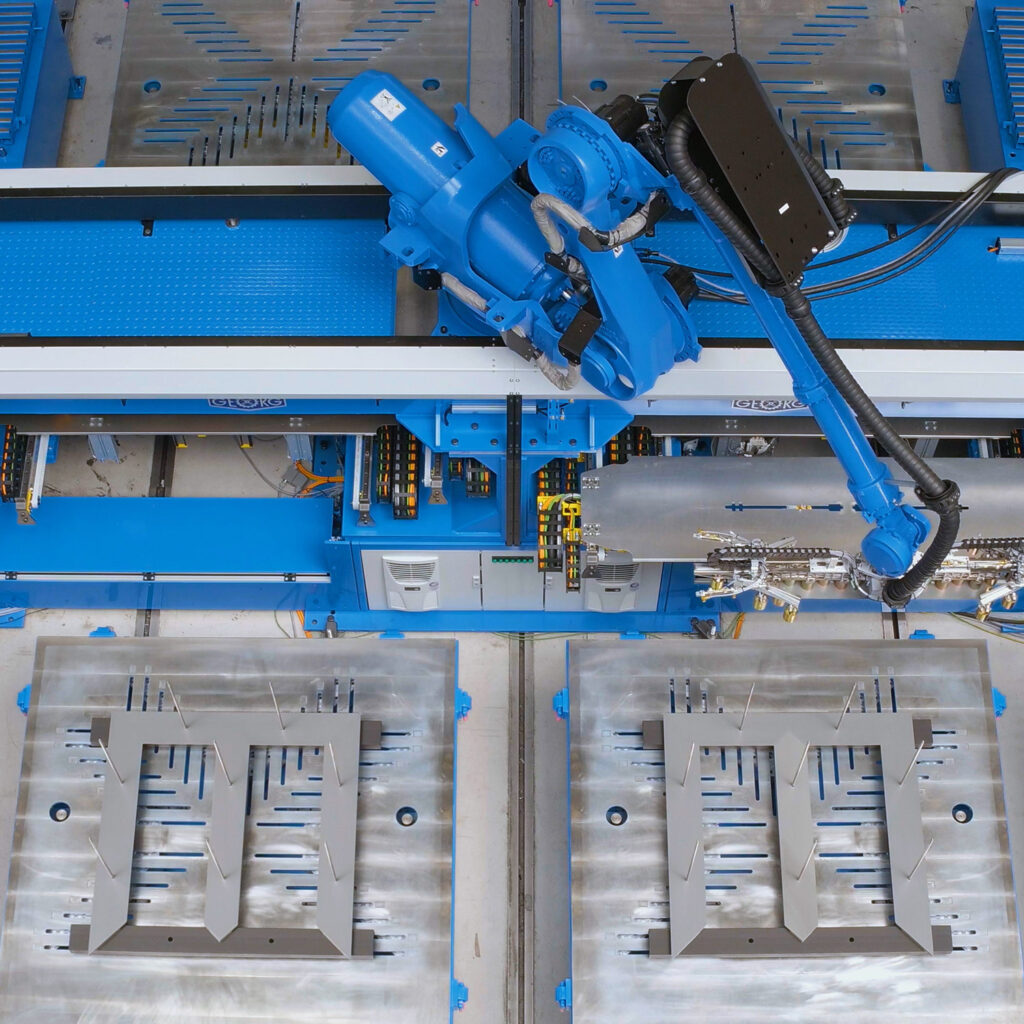

In addition to slitting lines, the product range also includes fully automatic E-stacking systems, which additionally improve line efficiency.

The transformer systems from Kreuztal are indispensable for the efficient production of low-loss transformer cores and are therefore used by all leading transformer manufacturers and cutting service centers worldwide. GEORG’s level of recognition in this market is almost 100%. The company benefits from its long experience in processing the surface-sensitive silicon tape for transformers.

Other product areas include the production of strip processing lines for the steel and non-ferrous metal processing industries as well as roll grinding machines. Here, too, the family-owned company from the Siegerland region is one of the world’s renowned and leading suppliers.

WORLD MARKET LEADER PRODUCT/S

Location

Employees

Sales Volume

Development of the „Liliputschere

Development of the world’s first transformer cut-off line (TBA) for grain-oriented electrical steel for transformer production

First TBA with fully automatic E-core stacking

Introduction of Ecoline lines

First TBA with a width of 1,250 mm

Introduction of Miniline lines

First high-speed transformer strip cut-off line TBA 400 with up to 140 sheets / minute

Introduction of transformer core stacking with articulated arm robots

Establishment of in-house, order-independent development department

Market launch of GEORG robotline TBA 400

Opening of a second location in North America (Atlanta, Georgia)

Market launch of the GEORG robotline TBA 300

Highest order backlog in the company’s history

Development of the world’s first inline measurement in TBA systems

Menü

The entrepreneurial success of hidden champions usually results from successfully occupying niche markets.