For over 60 years, the family-run company BIKAR from Bad Berleburg has been supplying customers from all industrial sectors with aluminium, copper, brass, bronze, special alloys and plastics. The material for each order is individually tailored to customer requirements.

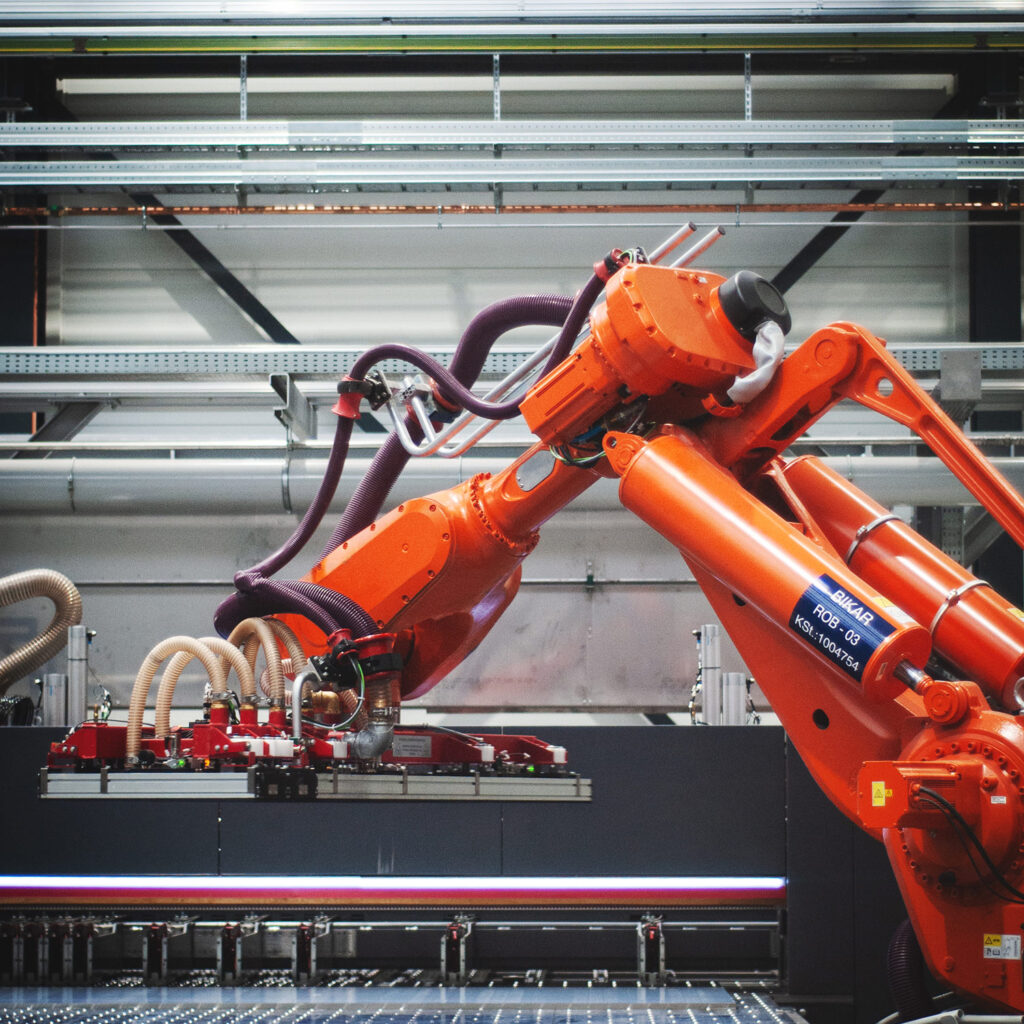

Ever since the company was founded, our top priority has been to think about the future and continuously develop the company. In doing so, we focus on automation, digitalisation and innovation. This is what has made BIKAR the market leader in the field of face-milled rolled plates for many years. With the BIKAR ZONE, our high-tech cutting center for aluminium rolled plates, we have now succeeded for the first time in the world in automating the production of non-standardised blanks in the manner of series production. From the storage of the aluminium plates to the packaging of the custom-made blanks, all work steps in the BIKAR ZONE are fully automated. Here, advanced robotics, driverless transport systems, pioneering sensor technology and software solutions developed in-house are combined with highly optimised control algorithms to form a unit that impresses with its precision and efficiency. We significantly reduce material consumption through automation. Specially developed systems for extracting and compacting the chips produced during the sawing process enable alloy-pure separation. This significantly increases recyclability and minimises the amount of material removed from the cycle.

Our development would not be possible without our team. With our strong focus on a culture of collaboration and a family atmosphere, our employees create the innovative solutions that put us at the forefront of the market. Each individual in the team contributes with their expertise and commitment to ensure that we meet our customers‘ requirements and constantly set new standards.

WORLD MARKET LEADER PRODUCT/S

Location

Employees

Sales Volume

Founded by Luise and Radomir Bikar

Opening of Plant II in Bad Berleburg Raumland: Cutting center for rolled products

Equipment of Plant III in Bad Berleburg-Raumland. The purpose was to cut aluminum blocks into cast plates

Foundation of „Bikar-Aluminium GmbH“ in Korbußen. In a series production process, cast aluminum ingots are sawn to different thicknesses, face-milled on both sides and then laminated. Bikar won the Thuringia Founder’s Prize for this. Change of name to „Bikar Aerospace GmbH“ in 2022.

Extension of two plants in Korbußen with an additional production area of over 17,000 m²

Construction of a special high-bay warehouse for bars and profiles and a new company headquarters at the headquarters in Bad Berleburg-Raumland

Commissioning of the BIKAR ZONE, the fully automated cutting center

Menü

The entrepreneurial success of hidden champions usually results from successfully occupying niche markets.