Heicks Industrieelektronik GmbH from Geseke is the European market leader for permanent sealing of electronic assemblies with extreme requirements. The company is the largest and only supplier in Europe that can assemble electronic assemblies according to aviation standards at one location, coat them with Parylene and selectively remove the coating again using a special laser. Heicks Industrieelektronik GmbH was founded in 1986 by Rudolf Heicks and initially produced electronic control devices in horticulture. After numerous expansions and the move to the current location in Geseke, the company’s production was expanded in 2007 to complement the previously almost unknown Parylene coating process.

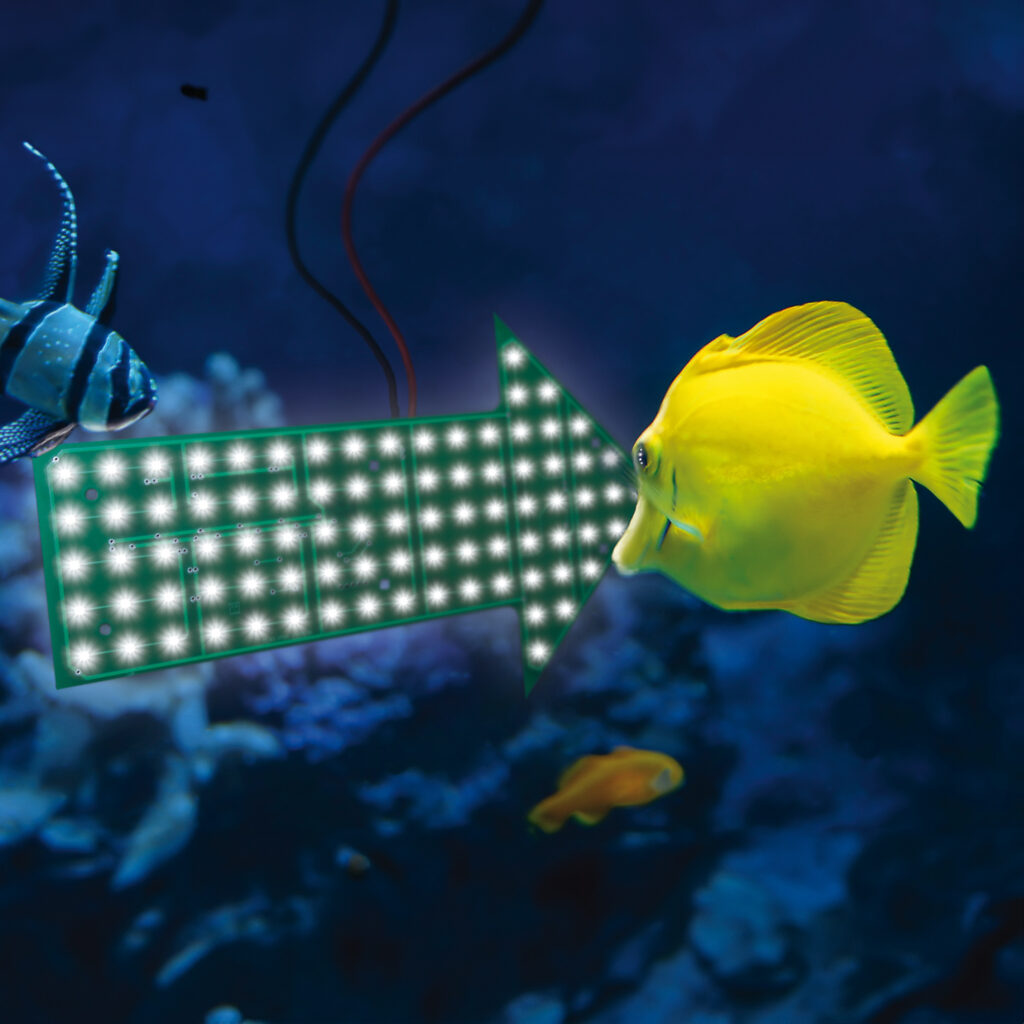

The coating with Parylene enables even coat application to the electronic assemblies. In contrast to other painting techniques, a consistent layer thickness is created here, even on the smallest unevenness. In this technique, a pore-deep and transparent polymer film is applied to the substrate in a vacuum-process through condensation from the gas phase (real conformal coating).

Virtually any substrate material (metal, glass, plastic, ceramic, ferrite and silicone) can be coated and hermetically sealed. The coating is especially used for electronic assemblies for the aerospace, medical technology and automotive industries. In these fields there are special requirements for the resilience of the electronics. Components coated with Parylene perform in a wide variety of applications, especially where components are exposed to particularly harsh environments. For example, in remote-controlled drones for the German Bundeswehr or control devices for Airbus and Boeing. But also documents can be coated with Parylene so that they are protected against moisture and damage.

WORLD MARKET LEADER PRODUCT/S

Location

Employees

Sales Volume

Company founded by Dipl.-Ing. Rudolf Heicks, production of electronic control devices in horticulture, later establishment of a printed circuit board production facility

Move to the new site in Geseke with approx. 2,500 m2 of production space

Expansion of production to include the Parylene coating process, which is virtually unknown in Germany

A further extension with 1500 m² of production space was completed and occupied

Plant 2 with additional 1200 m² production area occupied

First Aviation Certification acc. DIN EN ISO 9001 & EN 9100

Expansion of manufacturing technologies to include an X-ray counting device, PCB marking laser, 3D inline paste inspection, 3D inline AOI, new modern selective soldering system, cable packaging.

Menü

The entrepreneurial success of hidden champions usually results from successfully occupying niche markets.