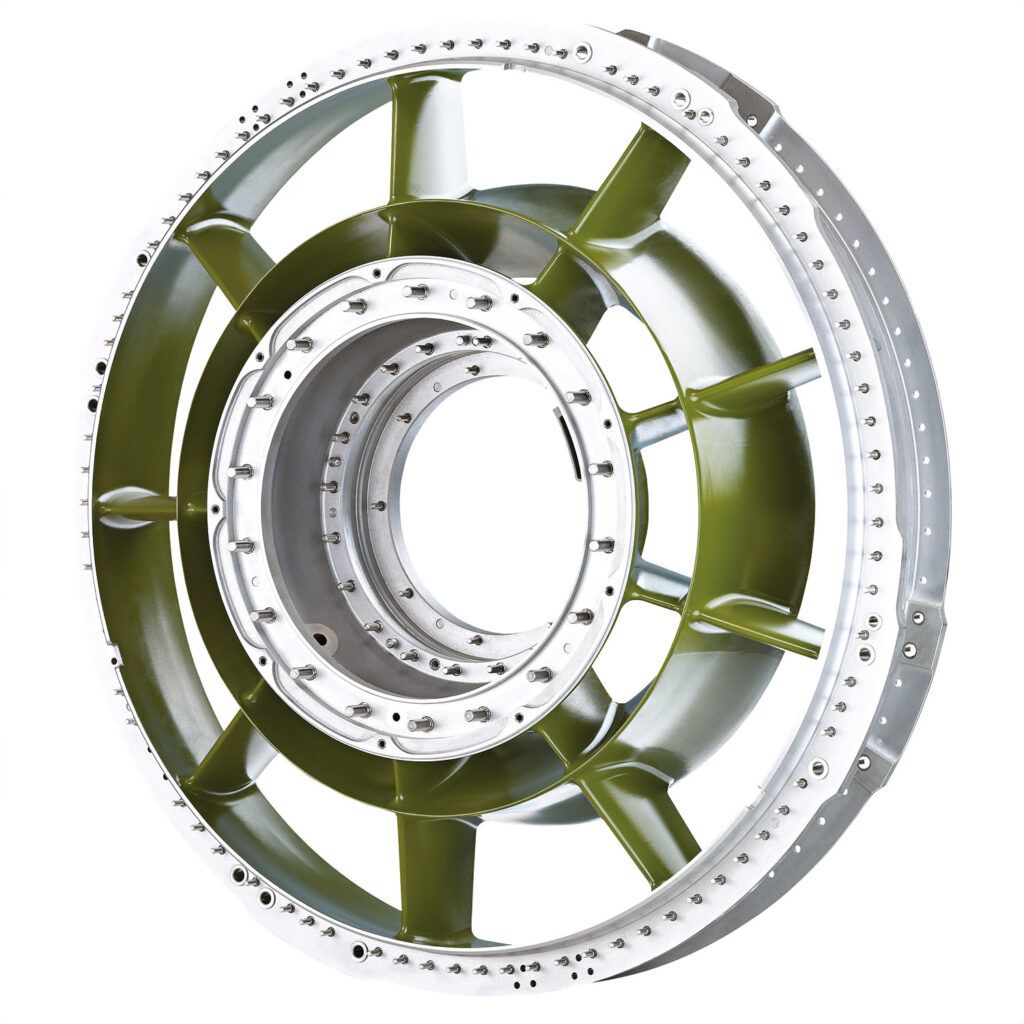

Tital GmbH, which belongs to the American group Howmet Aerospace, produces and sells investment casting products made of titanium and aluminum alloys and is one of the world market leaders in this segment. The company can produce castings up to 1.5 m in size and weighing up to 300 kg. It supplies companies in the aerospace industry, among others.

The castings are produced using the lost wax process. Titanium is an extremely strong and heat-resistant material, making it ideal for use in engines and other demanding areas of all civil and military aircraft.

The Hero-Premium-Casting® process, which has been patented since 1995, enables the production of lightweight aluminum components with above-average mechanical properties.

Its largest customers include companies such as Airbus and Safran. Tital also supplies components for the engines of the Eurofighter.

The investment casting specialist based in Bestwig employs around 700 people and was founded in 1974 by the companies W. C. Heraeus and Honsel AG. The company was taken over by its own management in 2006. In 2008, Titan-Aluminium-Feinguss GmbH changed its name to Tital GmbH.

In 2015, Tital GmbH was acquired by the US group Alcoa, which was split up in 2016 to form the new company Arconic. Arconic was also split up in 2020, creating the Howmet Aerospace Group.

WORLD MARKET LEADER PRODUCT/S

Location

Employees

Foundation of the company by the Honsel and Heraeus companies

Patent for HERO Premium Casting Process®

One of the largest titanium casting furnaces in Europe enables castings weighing up to 300 kg for the first time

Affiliation to the Arconic Group

Further demerger to form the Howmet Aerospace division

Menü

The entrepreneurial success of hidden champions usually results from successfully occupying niche markets.